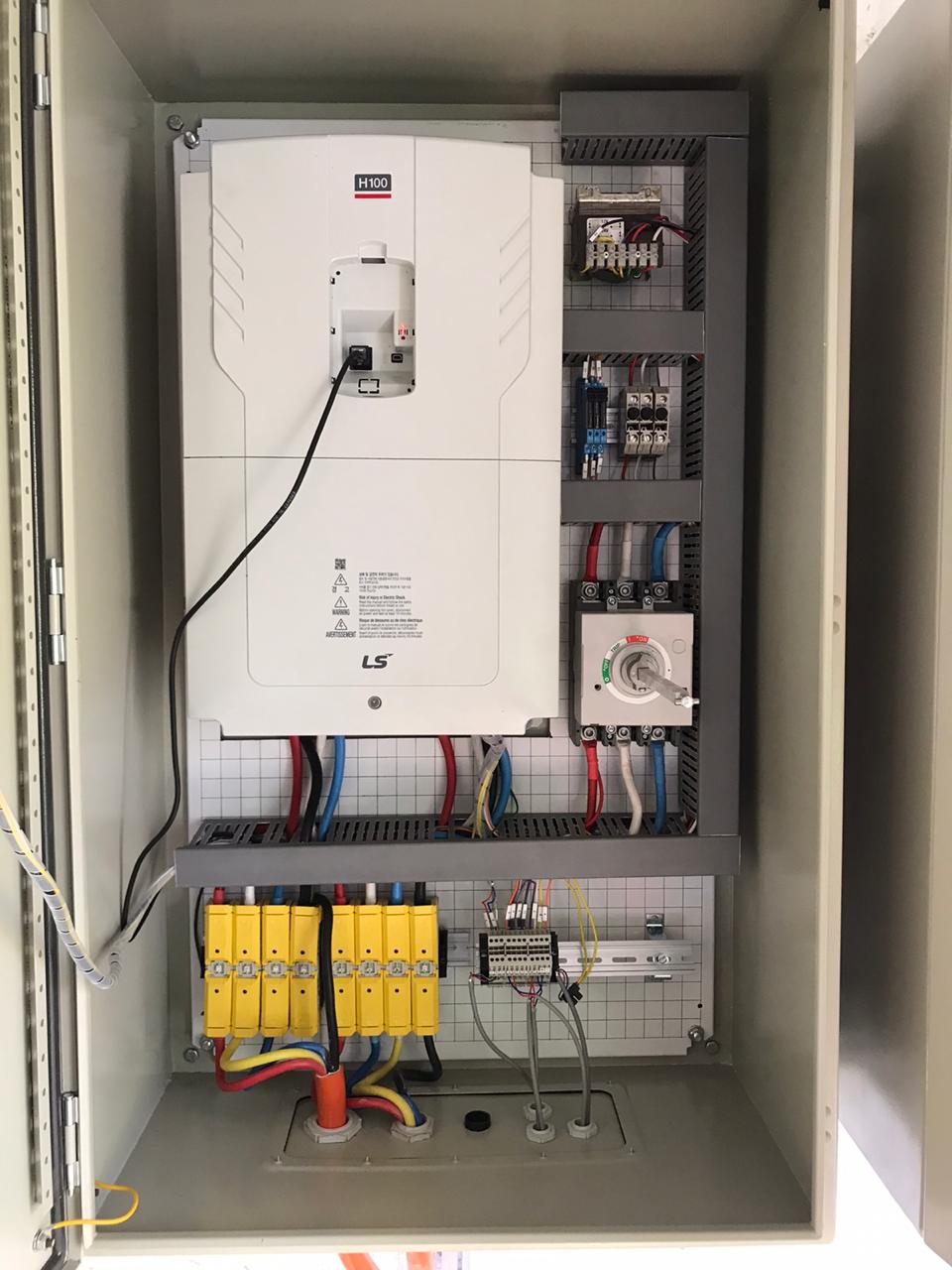

As we delve into the world of agricultural automation, we uncover the capabilities of the H100 VFD from LS Electric. Designed to meet the unique demands of irrigation systems, this cutting-edge technology promises not just efficiency, but sustainability—a promise that holds the potential to reshape the future of farming as we know it. Join us on a journey through innovation and discover how the LS Electric H100 VFD is powering the next generation of irrigation systems.

Soft Fill Operation

The initial operation of pumps can often lead to extreme pressure changes, potentially damaging equipment. With the soft fill operation feature, the H100 prevents such damage by mitigating pressure variations during the critical startup phase, safeguarding both pumps and pipelines.

He accomplishes this by incrementally increasing pressure through temporary setpoints in stages until reaching the final desired and overhead setpoint. It does so while PID is still applied to each stage.

Start Ramp & End Ramp

Pump damage during initial operation is a thing of the past with the H100’s start and end ramp functionalities. By adjusting acceleration and deceleration times, it ensures smooth transitions during pump startup and shutdown, reducing wear and tear on equipment.

Dec Valve Ramp

Sudden pressure changes when pumps stop or valves close can wreak havoc on systems. The H100’s dec valve ramp feature addresses this issue by allowing users to set deceleration times, preventing pump and pipe damage by ensuring controlled pressure adjustments.

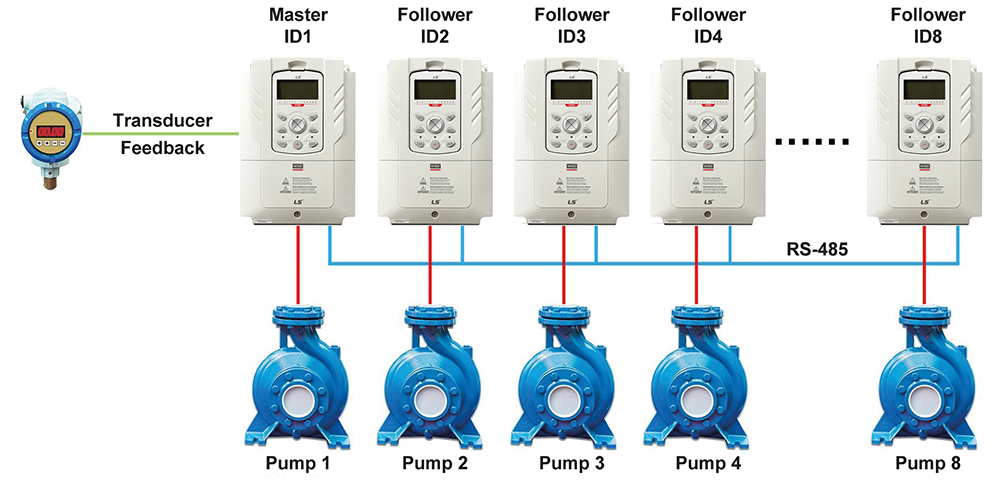

Multi Motor Control

This function is used to increase flow through the use of auxiliary pumps, when sufficient flow rate cannot be delivered from the main pump alone. The main motor controls the primary PID via feedback from the system pressure transducer, and operates/stops the secondary motor according to a set frequency.

Source: https://www.instrumentation.co.za/18978r

Scheduling (Time Event: Real-Time Clock)

Unpredictable pressure changes during pump operation can spell disaster. With scheduling capabilities based on real-time clock events, the H100 minimizes the risk of damage by ensuring pumps operate at optimal times, mitigating pressure fluctuations.

Flow Compensation

Long pipes often result in hydraulic losses, affecting system efficiency. The H100’s flow compensation feature addresses this issue by adjusting output frequency to compensate for losses, optimizing performance even in challenging environments.

Energy-saving Display (Payback Counter)

In today’s eco-conscious world, energy efficiency is non-negotiable. The H100 not only saves energy but also quantifies savings through its payback counter, providing tangible evidence of its impact on reducing energy consumption.

Power-on Resume

Power interruptions in the form of load-shedding are inevitable, but their impact on operations doesn’t have to be. With power-on resume functionality, the H100 picks up right where it left off, ensuring continuity in control commands and minimizing disruptions. No need to go start it manually after every load-shedding cycle.

Sleep, Sleep Boost, Wake-up

Energy conservation is a priority, even during standby periods. The H100’s sleep, sleep boost, and wake-up features optimize energy usage, putting the drive on standby when not in use and seamlessly restarting when needed.

Auto Torque Boost

Adaptability is key to efficiency, and the H100 delivers with its auto torque boost feature. By adjusting voltage output to match load requirements, it ensures optimal performance across a range of operating conditions.

Lubrication Control

Proper lubrication is essential for equipment longevity. With lubrication control, the H100 ensures that motors receive adequate lubrication before startup, prolonging motor life and reducing maintenance costs.

Damper Control

In systems with dampers, proper control is crucial for protection. The H100 commands damper operation as needed, ensuring system integrity and minimizing the risk of damage.

Detection of Pipe Broken

Early detection is the key to preventing catastrophic failures. With pipe break detection, the H100 alerts users to potential issues, allowing for timely intervention and preventing costly downtime. This feature can also be used to detect more than the required valves opening simultaneously preventing over-watering or fertilizing.

Level Detection

Maintaining system parameters within safe limits is essential for equipment longevity. With level detection, the H100 monitors frequency and voltage values, triggering protective measures when thresholds are exceeded.

Pre-Heat

Condensation can wreak havoc on motors, but pre-heating mitigates this risk. The H100 pre-heats motors during idle periods, ensuring optimal performance and prolonging motor life.

Under Load Protection

Protecting pumps from damage is a top priority, and the H100’s under load protection feature ensures just that. By issuing warnings and implementing protective measures, it safeguards pumps from dry running and other potentially damaging scenarios.

KEB, Kinetic Energy Buffering

Short power interruptions are inevitable, but they don’t have to be disruptive. With KEB, the H100 maintains voltage levels during power-dips, ensuring continuity of operations and minimizing downtime.

Pump Clean

Foreign substances in pumps can compromise efficiency and longevity. The H100’s pump clean feature removes such substances, optimizing pump performance and extending their lifespan.

Load Tuning

Understanding load characteristics is essential for optimal performance. With load tuning, the H100 establishes load curves based on frequency, providing valuable insights for system optimization.

In conclusion, the LS Electric H100 Inverter represents the pinnacle of industrial automation technology. With its advanced features, unmatched reliability, and commitment to efficiency, it’s not just a drive—it’s a game-changer. Whether it’s optimizing pump systems, maximizing energy savings, or ensuring system stability, the H100 is the ultimate solution for the challenges of today and tomorrow.